The discovery of the metallic element samarium in a Russian mine in 1879 marked the beginning of a new era in chemical synthesis. Named after the mineral samarskite, which was found in, samarium quickly became a crucial component in the creation of various molecules, especially those with pharmaceutical applications. The most common form of samarium reagent, samarium diiodide, has been instrumental in the synthesis of natural products like taxol, an anticancer agent. However, the practicality of using this reagent on an industrial scale has always been a significant challenge due to its air sensitivity and the formation of a pesky samarium-oxygen bond during reactions.

Overcoming Scalability Issues

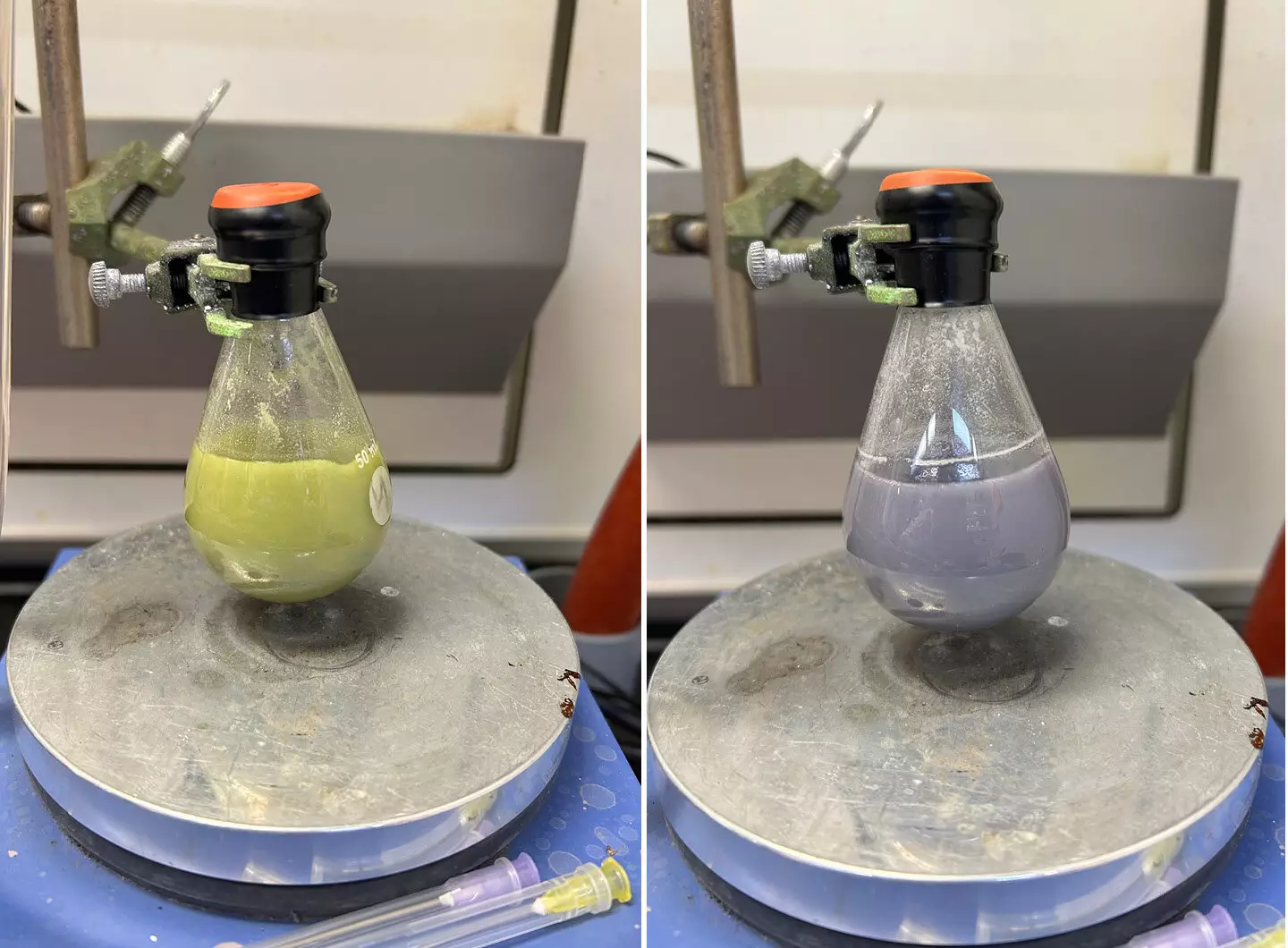

Caltech chemists, led by researchers Sarah Reisman and Jonas Peters, have recently made a groundbreaking discovery that addresses the long-standing scalability issues associated with samarium diiodide. Their study, titled “Reductive samarium (electro)catalysis enabled by SmIII-alkoxide protonolysis,” introduces a method that allows the reagent to recycle itself during a reaction, eliminating the need for large amounts of solvents and fresh preparations. This innovation opens up the possibility of translating complex academic reactions into industrial processes or discoveries. By breaking the samarium-oxygen bond using a mild acid, the researchers have found a practical solution for large-scale reactions that was previously unattainable.

The breakthrough achieved by the Caltech team not only solves the recycling issue but also paves the way for exploring new avenues in chemical synthesis. By working collaboratively across different research groups, such as the Reisman and Peters labs, scientists are able to leverage each other’s expertise to tackle complex challenges. For example, the Peters lab is focused on developing sustainable methods for nitrogen fixation, a process crucial for plant growth and food production. The samarium reagent, while previously limited to lab-scale reactions, now has the potential to play a significant role in advancing these research efforts towards industrial applications.

With the scalability barrier overcome, the possibilities for samarium reagents in chemical synthesis are now boundless. Researchers like Chungkeun Shin and Emily Boyd, co-lead authors of the study, are excited about the prospects of working with these versatile reagents on a larger scale. By collaborating with experts in different fields, they can explore new chemical reactions, optimize existing processes, and discover innovative solutions to pressing challenges in the pharmaceutical and agricultural industries. The ability to recycle samarium diiodide opens up new avenues for developing environmentally friendly and sustainable chemical synthesis methods that can benefit society as a whole.

The recent breakthrough in samarium reagents represents a significant milestone in the field of chemical synthesis. By addressing the scalability challenges associated with these versatile reagents, researchers have unlocked a new realm of possibilities for industrial applications. Collaborative efforts across different research groups have played a crucial role in driving this innovation and are essential for advancing the field of chemistry towards more sustainable and efficient practices. The future of samarium reagents looks promising, with the potential to revolutionize the way we approach complex chemical reactions and create new molecules with diverse applications.

Leave a Reply