In the quest for sustainable alternatives to petroleum-based plastic films, researchers at North Carolina State University have made significant progress. Through innovative research, they have combined chitosan, a biopolymer derived from crab shells, with agarose, a biopolymer extracted from seaweed, to create unique biopolymer composite films. These films possess exceptional strength, biodegradability, antibacterial properties, water repellency, and transparency, making them potential candidates for sustainable packaging films in the food and consumer goods industries.

The need to find sustainable replacements for synthetic polymers is a pressing concern. With the proliferation of plastic waste and the detrimental impact of petroleum-based plastics on the environment, researchers are turning to natural biopolymers as viable alternatives. However, simply mixing chitosan and agarose together is not enough. Previous attempts resulted in gritty films lacking sufficient strength. The challenge lies in modifying the joint structure of these natural polymers to achieve the desirable properties of synthetic polymers within a sustainable, biodegradable film.

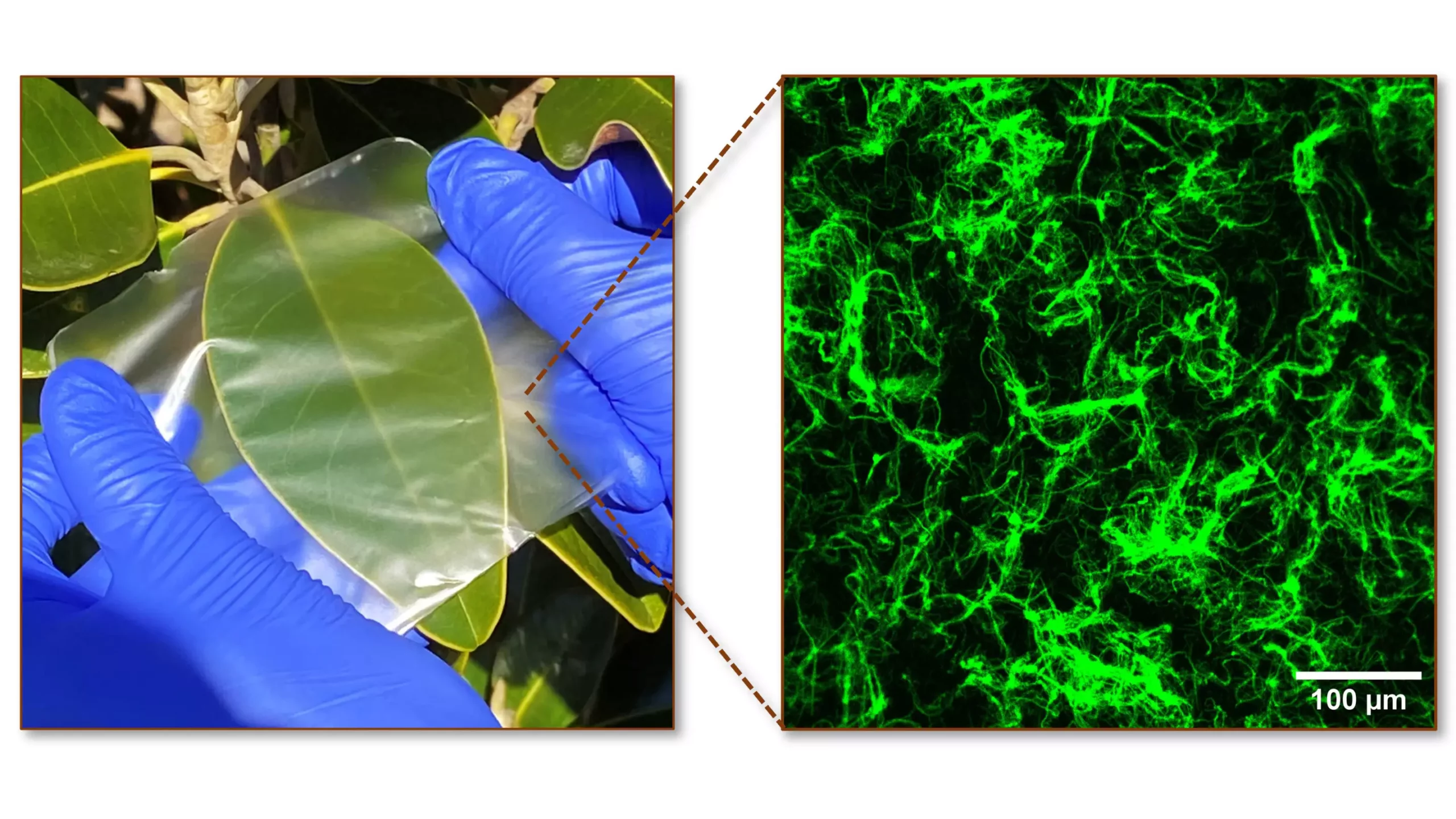

To overcome the limitations of previous mixtures, the team at North Carolina State University took a different approach. They reinforced agarose films with soft dendritic colloids, a fibrillated colloidal scale material derived from chitosan. These chitosan micro- and nanoscale fibrils possess hierarchical branching, providing the necessary strength and stability to the agarose film in which they are embedded. By altering the morphology of natural polymers and using them as composites, the research team achieved significant improvements in mechanical properties. Furthermore, the compatibility and opposite charges of chitosan particles and agarose resulted in enhanced resistance to water.

The findings of the research demonstrate that the biopolymer composites are approximately four times stronger than agarose films alone. Additionally, these films exhibit resistance to E.coli, a commonly studied bacterium. Enthusiastically, a sheet made from biopolymer composite films significantly degraded after a month underground, while a conventional plastic sandwich baggie remained intact. This degradation process is an essential aspect of sustainability, as the composite films are initially strongly antibacterial but eventually biodegrade due to their natural composition.

Although the research has showcased promising results, there is still work to be done. The researchers aim to further enhance the structure of these biopolymer composite films with the ultimate goal of matching the properties of synthetic polymers. Impermeability to oxygen and water is crucial in food packaging, and efforts will be focused on making the films more resistant to these elements. Additionally, increasing the scalability of the material production process is necessary to meet large-scale demand. The researchers envision a continuous and rapid process akin to papermaking.

The innovative combination of chitosan and agarose has brought us closer to a sustainable solution for packaging films. Through structural enhancements and the incorporation of natural biopolymers, the research team at North Carolina State University has created films with exceptional properties. These biopolymer composite films not only possess enhanced strength, antibacterial capabilities, and water repellency but also biodegrade over time. As the research continues, it holds the promise of revolutionizing the packaging industry by offering environmentally friendly alternatives to petroleum-based plastics. The future of sustainable packaging is within reach.

Leave a Reply