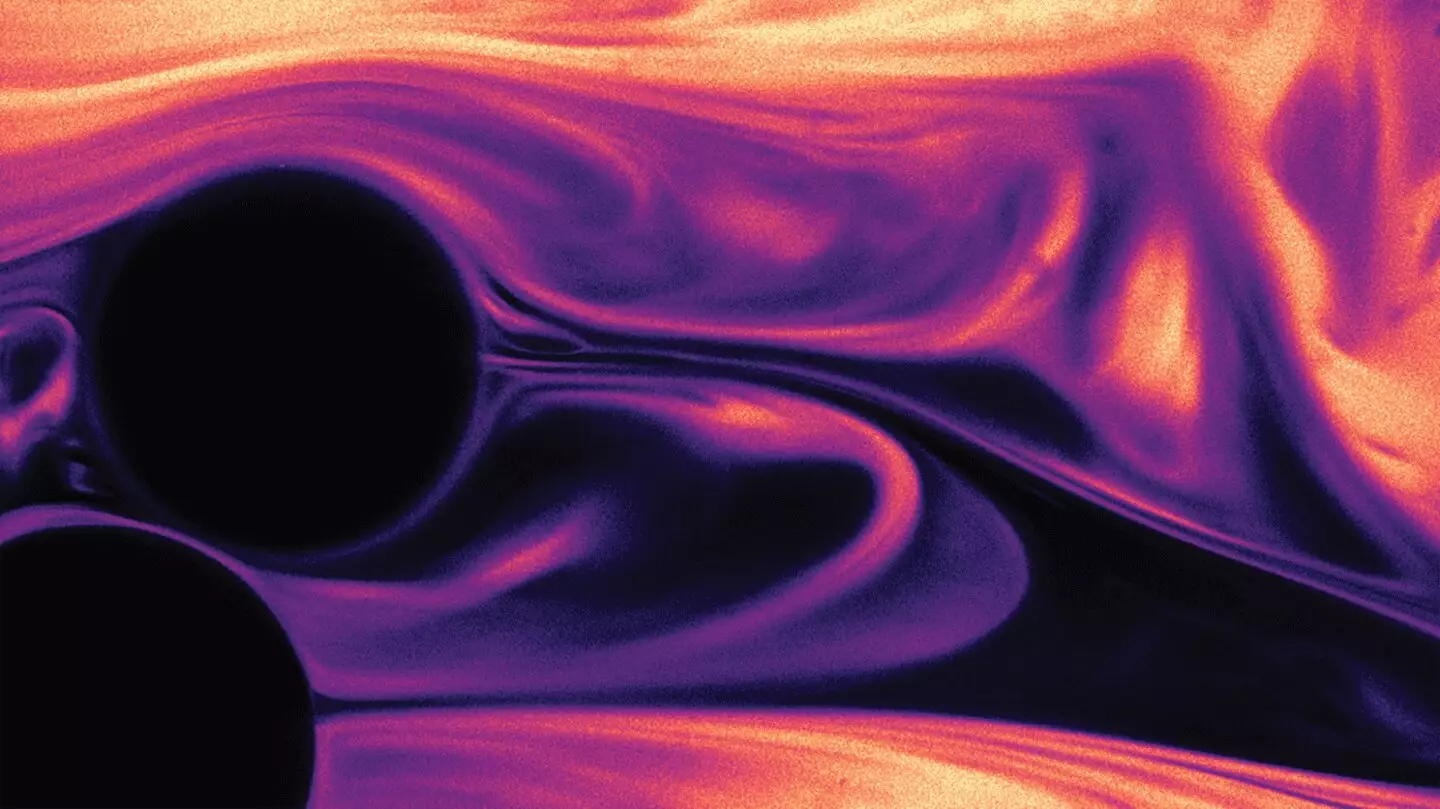

When you observe the mesmerizing swirl created by pouring cream into a cup of coffee, you’re witnessing a captivating dance of physics. The fluid dynamics involved resemble the grandiose storms of Jupiter, with chaotic eddies and whirlpools that create a temporary beauty in a simple act. Yet, this visual phenomenon is far more than just a delightful moment in your daily routine; it embodies a fundamental scientific process that is critical in various industrial applications.

The intricate art of mixing is at the core of many manufacturing processes—from the creation of plastics to chemical formulations. Industries depend on mixing to combine disparate substances, ensuring the quality and consistency of products we often take for granted. But unlike the carefree mixing in a coffee mug, industrial processes can be more complex and challenging, particularly when they involve granular materials or fluids passing through packed beds. This scenario is akin to brewing a fine espresso, where the geometry and spacing of packed grounds influence the outcome profoundly.

The challenge in many industrial applications lies in achieving effective mixing in environments that often do not allow for turbulence. Traditional methods in chemical engineering frequently face limitations when trying to mix fluids effectively in confined spaces, such as packed beds filled with grains. The limited volume in these spaces curtails the chaotic mixing that is essential for driving chemical reactions forward. Consequently, engineers have long searched for innovative solutions to enhance this mixing process.

In light of these obstacles, a team of researchers at Princeton Engineering has made a groundbreaking discovery: by introducing elastic polymers into one of the fluids in the mixing process, they can mimic the turbulent mixing that typically occurs in larger volumes. This research represents a potential watershed moment for fields such as plastics manufacturing, carbon capture, and even environmental remediation.

The research led by Christopher Browne, along with mentor Sujit Datta, has tremendous implications. By integrating stretchy polymers that behave in unexpected but beneficial ways at microscale levels, the study has demonstrated the ability to transform mathematically and materially how we approach mixing. The innovative use of polymers, which share characteristics with everyday absorbent materials yet can be fine-tuned for specific applications, holds promise for making industrial processes faster and more efficient. Remarkably, this new approach can enhance reaction rates by up to tenfold, thus leveraging common materials for extraordinary outcomes.

Browne’s journey through this research encapsulates both the challenges and discoveries that come with scientific exploration. Through various studies, he painstakingly addressed the interplay of fluids and polymers within confined spaces, leading to unpredictable yet beneficial results in chemical reaction rates. What makes this research unique is not just the findings themselves; it’s also the methodology and insights gained along the way, underscoring the principle that sometimes stepping back can bring fresh insight.

One of the most striking advantages of this new mixing technique lies in its scalability. Traditional methods focused on altering the geometry within packed beds can be prohibitively expensive or entirely unfeasible, particularly in cases like aquifers or chemical plants. Instead, the approach favored by Browne and Datta utilizes simple, widely available materials that can be adapted across different porous environments. The elegance of this solution broadens its applicability and offers a pathway toward more sustainable production processes.

The aesthetic beauty of chaotic mixing shouldn’t be overlooked either. Beyond the practical applications, these findings can enrich our understanding of fluid mechanics and inspire future studies. These scientists have not only advanced the field of chemical engineering but also engaged with the natural curiosity inherent in scientific inquiry—demonstrating that beauty can indeed arise from complexity.

What this research unveils is not merely a novel mixing technique; it heralds a new era in how we understand interaction between materials at micro levels. With its roots in everyday experiences like mixing coffee, the implications stretch far beyond simple illustrations, reaching into the heart of engineering challenges that impact various fields. The potential to increase efficiency in chemical production, reduce costs, and make processes more environmentally friendly signifies a vital shift in scientific and industrial approaches.

As industries strive to innovate and adapt in an ever-evolving landscape, the insights derived from studies such as Browne’s stand to shape the future of not just mixing, but entire sectors reliant on chemical reactions and compound interaction. With the groundwork laid by these researchers, we can anticipate a wave of advancements that optimize processes and drive the next revolution in industrial engineering.

Rogue waves have long been a subject of fascination and terror in maritime lore. These…

As the world grapples with public health challenges, especially those posed by infectious diseases, the…

The Sombrero Galaxy, also known as Messier 104, embodies a breathtaking blend of spirals and…

In recent advances in quantum electronics, a groundbreaking discovery leveraging the concept of kink states…

In the intricate tapestry of nature, ice often exists in a delicate balance with liquid…

In an astonishing event that captured global attention, a rogue object from beyond our Solar…

This website uses cookies.