Three-dimensional (3D) printing has seen significant advancements over the years, with the ability to create toys, furniture, and electronic components. As the cost of 3D printing equipment decreases, it could also be used to fabricate soft electronic components for wearable devices. However, 3D printing has seldom been used to produce flexible electronics due to the difficulty in printing solid-state elastic materials that can conduct electricity.

Researchers at the Korea Institute of Science and Technology have successfully demonstrated the use of 3D printing to create elastic components that conduct electricity. Their proposed printing strategy, which is outlined in a paper in Nature Electronics, could pave the way for the large-scale printing of multi-functional and stretchable components for wearable devices.

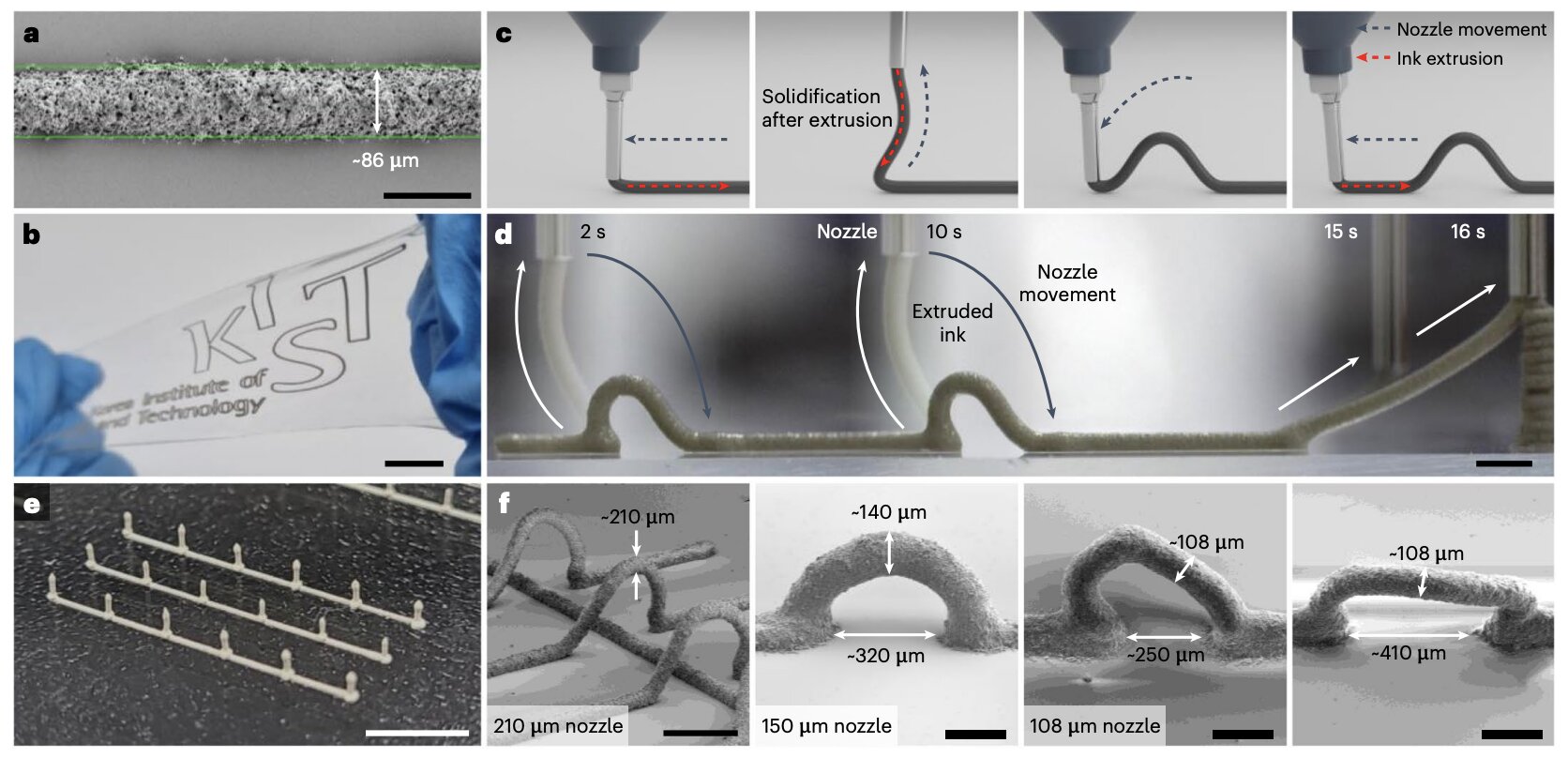

The team was able to create elastic conductors using 3D printing thanks to a new emulsion-based composite ink they developed. This ink consists of liquid components dispersed within a conductive elastomer, which is a rubbery material that conducts electricity. The composite ink has several advantageous properties compared to other inks commonly used in 3D printing, such as viscoelasticity, shear-thinning, and lubricating properties that better support the printing of complex 3D structures.

Creating Soft Electronics for Wearable Devices

According to the researchers, the emulsion system can be used for the omnidirectional printing of elastic conductors, making it possible to print filamentary, out-of-plane, and freestanding three-dimensional geometries directly. The composite ink provides structural integrity to the printed features and prevents nozzle clogging. The team was able to demonstrate the potential of their 3D printing approach and emulsion-based ink by printing elastic interconnects, which they used to create a wearable temperature sensor with a stretchable display.

Lee, Cho, and their colleagues also highlight the possibility of combining their approach with 3D scanning technologies to create soft electronics that align perfectly with the shape of the human body, making them more comfortable for users to wear. Additionally, the ink they created could inspire the creation of other emulsion-based inks that operate similarly but are based on different compositions and elastomers.

In conclusion, the researchers’ proposed printing strategy and emulsion-based composite ink pave the way for the large-scale printing of multi-functional and stretchable components for wearable devices using 3D printing. The successful use of 3D printing to create elastic conductors could lead to the creation of various other stretchable and conducting components, making wearable devices more comfortable and efficient.

Leave a Reply