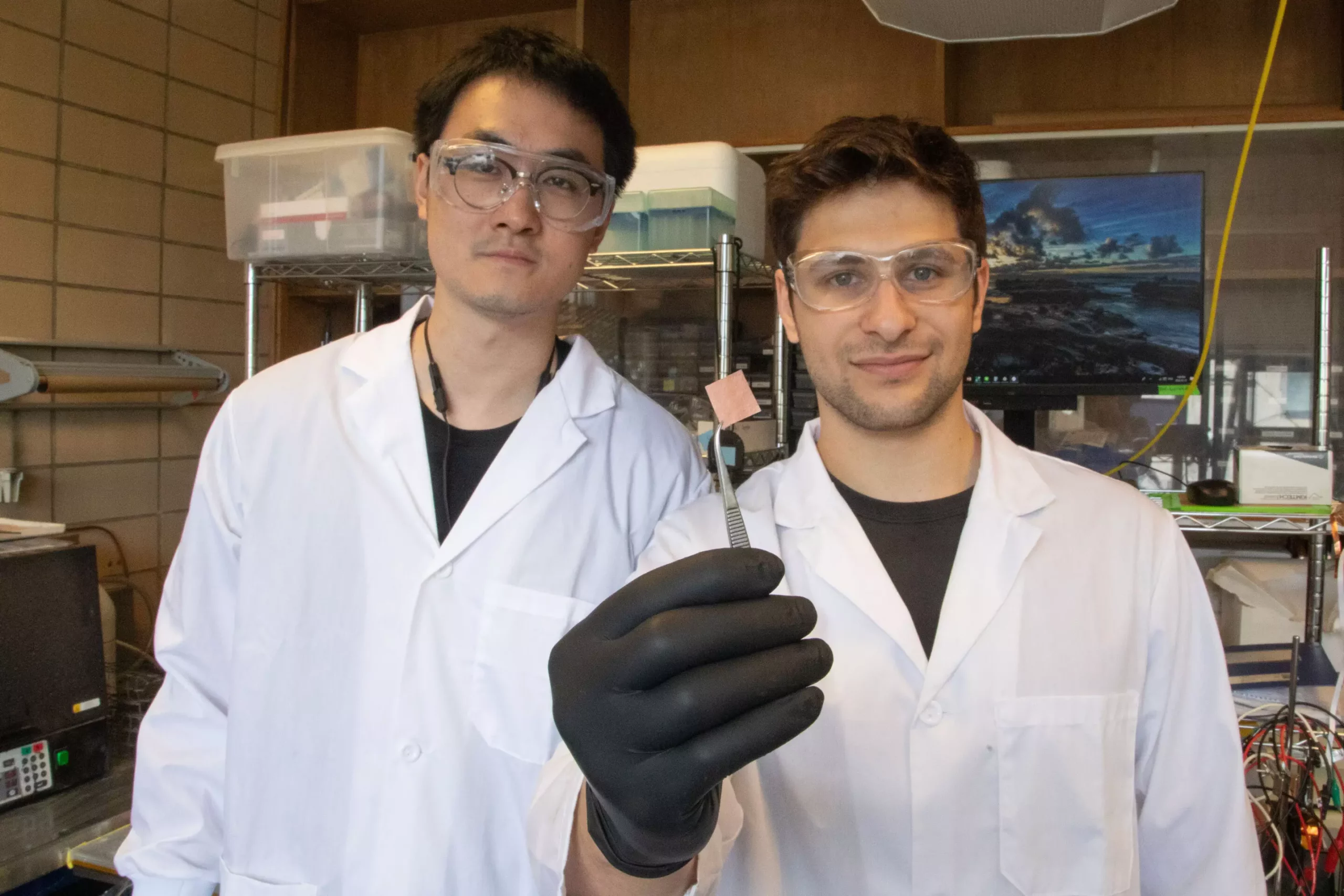

Researchers at the University of Toronto Engineering have developed a groundbreaking catalyst that efficiently converts captured carbon into valuable products, overcoming the challenges posed by contaminants that degrade the performance of existing catalysts. This discovery represents a significant advancement in the field of carbon capture and storage, offering promising prospects for integrating these technologies into industrial processes.

While the availability of low-carbon electricity generation options has expanded in recent years, certain sectors such as steel and cement manufacturing present greater challenges for decarbonization. In order to support these industries in reducing their carbon footprint, there is a critical need to develop cost-effective methods for capturing and upgrading carbon emissions from their waste streams.

The research team, led by Professor David Sinton, utilizes electrolyzers to convert carbon dioxide (CO2) and electricity into valuable carbon-based products like ethylene and ethanol. These products can be utilized as fuels or as feedstocks for the production of various everyday items. Within the electrolyzer, the conversion process occurs at the solid catalyst’s surface, involving the interaction of CO2 gas, electrons, and a liquid electrolyte.

Unlike traditional catalysts designed to operate with pure CO2 feedstocks, the newly developed catalyst by the University of Toronto Engineering team can effectively process impure carbon streams containing contaminants like sulfur oxides (SO2). These impurities typically poison catalysts by reducing reaction efficiency and generating undesirable byproducts. To address this challenge, the research team made two critical modifications to a standard copper-based catalyst.

Impurities like SO2 pose a significant threat to the efficiency and longevity of catalysts working with carbon-rich streams. Despite existing methods to remove contaminants from exhaust gases, these processes are time-consuming, energy-intensive, and costly. Even minimal amounts of SO2 can rapidly deteriorate catalyst performance, emphasizing the importance of developing catalysts that can withstand impurities.

The innovative catalyst design includes a thin Teflon layer on one side and a Nafion layer on the other, providing protection against SO2 poisoning. The Teflon layer alters the catalyst surface chemistry, hindering the reactions required for SO2 binding. On the contrary, the Nafion layer’s porous structure prevents SO2 from reaching the catalyst surface, ensuring sustained performance even in the presence of contaminants.

In experimental trials with a mix of CO2 and SO2, the newly developed catalyst exhibited remarkable resilience, maintaining a high Faraday efficiency of 50% over 150 hours of operation. This long-term stability underscores the potential of the catalyst for industrial applications, paving the way for enhanced carbon capture and conversion processes. The researchers plan to further explore the catalyst’s performance against a broader range of chemical impurities to expand its applicability.

The development of a robust catalyst for converting carbon emissions into valuable products represents a significant breakthrough in the quest for sustainable carbon capture and utilization technologies. By addressing the challenges posed by contaminants like sulfur oxides, this innovative solution offers a promising pathway towards decarbonizing industrial sectors and advancing the transition to a greener economy.

A groundbreaking discovery by scientists at the University of Manchester is poised to reshape the…

In an era marked by rapid ecological change, the quest for understanding environmental pollutants like…

The meteoric rise of artificial intelligence (AI) technologies is not without significant implications on our…

The landscape of quantum computing is on the verge of transformative progress, fueled by groundbreaking…

Schizophrenia is not merely a mental health issue; it is a multifaceted condition that wreaks…

Recent scientific research has illuminated the intricate web that ties our dietary choices to the…

This website uses cookies.